Here's How: Tips for Pouring Concrete Driveway

Dear James: I plan to have my asphalt driveway replaced with concrete. My neighbor's cracked after on a few years. What should the contractor to do so mine holds up? -- Dave S.

Dear Dave: Your driveway is the first thing that most people see when visiting your house, and a deteriorated one can be a real eyesore. If installed with the proper materials and the procedures, a concrete driveway should last through a lifetime of cars, foot traffic and projects.

Installation errors by the contractor are the most common cause of failures of concrete driveways. Since the concrete is almost always premixed at the plant and delivered by truck, the concrete material itself is very seldom the cause of the problem.

One potential problem, which the contractor has no control over, is road salt damage. The salt does not damage the concrete directly, but it passes through the pores in the concrete and reaches the reinforcing steel rods (called rebar). When the rebar rusts, it expands and can fracture the concrete.

In cold climates, where road salt is used, it can damage your driveway even if you do not spread it out yourself. Just the salty water dripping from beneath your car will penetrate the concrete and can be enough to damage the driveway.

Always use a clear sealer over the concrete once it has fully cured. You can find it at most hardware and home center stores or contact the following manufacturers: Dow Corning, Chem Rex, and Saver Systems.

When you contact contractors to pour and finish your driveway, do not just accept the lowest bid on the job. Particularly with concrete work, there are many ways for the contractor to cut corners and save money, and your driveway will just end up looking like your neighbor's in a few years.

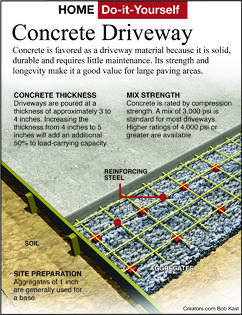

A solid base is critical to a long-lasting concrete driveway. Concrete is extremely strong in compression, but fairly weak when stretched, bent or twisted. Once your old asphalt driveway is removed, the contractor may revise the bid depending on the quality of the base and the extra work that may be required to improve it.

It is important to make sure that your contractor will use 4,000 psi (pounds per square inch) concrete mix. This is generally acceptable for residential driveways. Some contractors will suggest a 4-inch thickness, which may work, but request a 5-inch thick driveway. For a typical driveway, the extra inch will cost about $100 to $150 more for materials.

Reinforcing steel rods should be embedded in the concrete, just a couple of inches below the surface. They should not be laid on the ground. The driveway surface should be sloped to the sides so that water runs off. A slope of 1 inch in every 10 feet should be adequate.

Although concrete looks rigid, it does shrink as it cures, and it gets stressed as weather conditions change. This usually causes cracks to form. The contractor should locate control joints (deep grooves) across the driveway spaced the same as the width of the driveway (creates squares). When it cracks, it will occur along the joints and will not be noticeable.

The best type of surface for a driveway is a light broom or wood trowel finish. This provides plenty of traction and should be fine for basketball games and the like. Avoid a slick steel trowel finish as is often used in basements and other interior slabs.

Once the concrete is poured and the surface is finished, it must be given time to cure. Depending on the weather conditions, it should usually be covered with plastic so that the surface does not dry out too fast. The reaction between the cement and the water is what creates its cured strength.

========

Send your questions to Here's How, 6906 Royalgreen Dr., Cincinnati, Ohio, 45244 or visit www.dulley.com. To find out more about James Dulley and read features by other Creators Syndicate writers and cartoonists, visit the Creators Syndicate website at www.creators.com.

Copyright 2024 Creators Syndicate Inc.

Comments