Why Trump's dream of made-in-the-USA iPhones isn't going to happen

Published in Business News

For U.S. President Donald Trump, there would be few bigger victories than having a domestically produced version of the iPhone, one of the most popular tech products in history. Such a prize would validate his tariff plan and campaign promise to bring manufacturing jobs back to America.

And the administration clearly feels this is an achievable goal, especially in the face of the 145% tariffs that it aims to impose on imports from China, Apple Inc.’s current manufacturing hub. The company also has vowed to invest $500 billion domestically over the next four years.

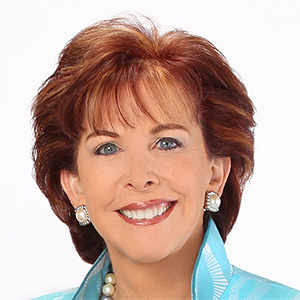

This week, the White House made its stance clear: Trump wants Apple to begin building the device in the U.S. “If Apple didn’t think the United States could do it, they probably wouldn’t have put up that big chunk of change,” White House Press Secretary Karoline Leavitt told reporters.

But the reality is far different. Apple is unlikely to move iPhone production to the U.S. in the foreseeable future for a variety of reasons, including the shortage of facilities and labor needed to produce the devices. Moreover, the country lacks the rich ecosystem of suppliers, manufacturing and engineering know-how that — for now — can only be found in Asia.

The company also is more focused on turning India into its new source of U.S.-bound iPhones. Apple’s partners are building the world’s second-largest iPhone plant in that country, decreasing the company’s reliance on China.

Apple’s biggest FATP facilities — short for final assembly, test and pack-out — are massive and incomprehensible to many people outside of Asia. They are almost towns themselves, with several hundred thousand people, schools, gyms, medical facilities and dormitories. One major iPhone factory, a complex in Zhengzhou, has even been dubbed iPhone City.

“What city in America is going to put everything down and build only iPhones? Because there are millions of people employed by the Apple supply chain in China,” said Matthew Moore, the co-founder of a startup and a former Apple manufacturing engineer. “Boston is over 500,000 people. The whole city would need to stop everything and start assembling iPhones.”

A representative for Cupertino, California-based Apple declined to comment.

The development of new iPhones and other products still starts at Apple’s labs in Silicon Valley. But working with Asia-based component suppliers and other partners begins long before a product actually hits the market. Apple engineers and operations experts spend months or years working closely with Foxconn Technology Group, Pegatron Corp. and other suppliers to customize assembly of new devices.

In addition to its lock on the manufacturing operations, China is home to millions of people educated in operating machinery and the skills needed to build iPhones — a process that still requires a lot of manual work.

“The engineering support to run a factory is not in America,” Moore said. There just aren’t enough students studying STEM, or science, technology, engineering and math, he said.

Chief Executive Officer Tim Cook laid out the reasons for relying so heavily on China during a Fortune magazine event in 2017, saying it wasn’t because of low labor costs.

“China stopped being the low labor cost country many years ago,” he said. “The reason is because of the skill and the quantity of skill in one location.”

You could fill multiple football fields with state-of-the-art tooling engineers in China, Cook said that the time. “In the U.S., you could have a meeting of tooling engineers and I’m not sure we could fill the room.”

One popular counterpoint is that Apple should use its cash hoard to buy thousands of acres in the U.S. and create a fully robotic and automated iPhone manufacturing facility. That would remove any human-related challenges from the manufacturing process.

Commerce Secretary Howard Lutnick said as much in an interview with CBS, suggesting that “the army of millions and millions of human beings” is going to be automated.

But that’s not yet realistic, according to supply chain experts and people who have worked on Apple product manufacturing. China has access to lower-cost automation and hasn’t been able to make such a vision work.

The pace of iPhone development also makes it harder to automate processes because they can frequently change, they said. Much of the equipment needed for production is made in China as well.

While the look of the iPhone hasn’t changed meaningfully in years, new materials and internal components — and even the smallest of tweaks to the design — require the company to retool the assembly lines overseas.

“You design the thing, rebuild the factory, and then you only have six months to sell it,” according to a person with knowledge of Apple’s supply chain who asked not to be identified. “The pace of change makes it so much harder to automate.”

Though Apple has indeed diversified production of iPhones, reducing the share made in China to below 90%, it’s difficult to duplicate the process in other countries. Apple production hubs in Thailand, Vietnam, Malaysia and Indonesia are focused on devices like Macs, AirPods, smartwatches and iPads.

So far, the biggest attempt to create an iPhone manufacturing center outside of China has been in India. And that’s taken a decade to come together. Though Apple has a small iPhone manufacturing line in Brazil, that operation is focused on less-advanced models.

For now, at least, the Indian factories will help Apple avoid the Chinese tariffs. Already the company has been filling its U.S. channels — its biggest single market — with iPhones made in India, Bloomberg News previously reported. That country could also be enough, at least for now. The estimated 35 million units it’s now making a year could cover a large portion of its needs in the U.S.

Apple sells more than 220 million iPhones a year and currently offers seven models, which are all sold in multiple colors and storage capacities. That makes the manufacturing process even more complex and the scale offered in China even more important.

According to Moore, simpler products with less frequent changes — like iMacs and iPads — could be easier. Already, Apple handles final assembly of Mac Pro desktops in Texas. But the parts being pieced together are mostly made in China anyway. Moreover, Apple only sells thousands of those computers annually and doesn’t update them for years at a time.

“IPhones are a different animal,” Moore said.

_____

©2025 Bloomberg News. Visit at bloomberg.com. Distributed by Tribune Content Agency, LLC.

Comments